Professional Manufacturer of CNC Angle line, angle punching machine, plate processors, plate punching machine, plate drilling machine, beam drill saw line and other machines for Iron tower, steel structure and metal steel sheets.

- APLD1010/APLD1010C CNC Angle Punching Marking&Shearing Line

- APL1412,APLD1412,APLD1412A CNC Angle Punching Marking&Shearing Line

- APL1516,APL1516A (Enhanced)CNC Angle Punching Marking&Shearing Line

- APL2020, APLH2020, APLD2020 CNC Angle Punching Marking&Shearing Line

- APL2532, APL3640 CNC Angle Drilling Marking Line

- APLH2532, APLH3635 CNC High Speed Angle Drilling Marking Line

- CPP103, CPP123 CNC Steel Plate Punching Marking Machine

- CPD103, CPD104 CNC Hydraulic Plate Punching Marking Drilling Machine

- CPP067 CNC Hydraulic Plate Punching Machine

- PL065A CNC Flat Bar Channel Steel Punching Marking&Shearing Line

- AHM100 Hydraulic Marking Machine

- MFP140 Hydraulic Notching Machine

- DPD1610, DPD2016, DPD3016 CNC Plate Drilling Machine

- PLD2012, PLD2016, PLD3016 CNC Steel Plate Drilling Machine

- PHD2012/PHD2016/PHD3016 High Speed CNC Drilling Machine

- PHD2020/PHD3030/PHD4040 High Speed CNC Drilling Machine

- TDD400 TDD700 Beam Drilling Machine

- TDD1000 TDD1250 CNC Beam Drilling Machine

- THD1000 THD1250 CNC High Speed Beam Drilling Machine

- VBS1000 VBS1250 Band Saw

- NBS1000 NBS1250 CNC High Speed Band Saw Machine

- LBM38 LBM55 CNC Beam Beveling Machine

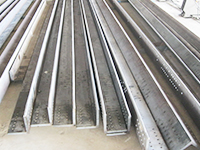

The machine is the special equipment used for angle steel drilling & marking mainly in the field of angle steel tower industry.

1. Transverse Conveyor |

2. Rotating Loading System with Rotating Motor |

3. Infeed Conveyor and CNC Controlled Carriage |

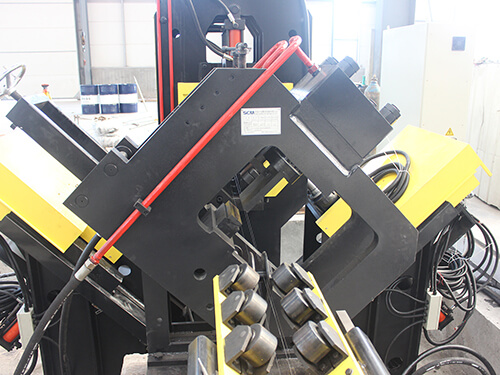

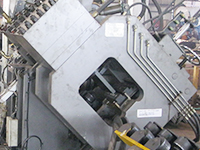

4. Machine Host Including Drilling, Marking & Shearing Unit (Optional Part, Max. Shearing Size 200×200×20mm) |

5. Unloading Conveyor |

6. Hydraulic Unit |

7. Electrical Cabinet |

1. Angle processing size: TBL2532 (140×140×10-250×250×32mm), TBL3535 (140×140×10-250×250×32mm).

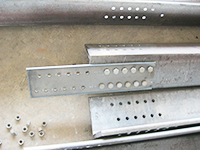

2. Functions: Drilling, Marking.

3. Quantity punches on each side: 3 (Can install three different kinds of drill bits).

4. NC carriage feeding, more faster and precision more higher.

5. Double accumulators(Which are located above the host and the hydraulic station), improve the speed of punching and production efficiency.

Model |

TBL2532 |

TBL3535 |

Angle size (mm) |

140×140×10~ 250×250×32 |

140×140×10~ 350×350×35 |

Marking force (kN) |

1030 |

1030 |

Max. length of blank (m) |

14 |

14 |

Max. length of finished (m) |

14 |

14 |

No. of drill on each side |

3 |

3 |

No. of character group |

1 |

1 |

No. of character |

15 |

15 |

Character size (mm) |

14×10×19 |

14×10×19 |

Range of stadia (mm) |

50~220 (Stepless) |

250~320 (Stepless) |

No. of CNC axes |

3 |

3 |

Spindle rotation speed (r/min) |

180-560,Transducer stepless adjustment |

180-560,Transducer stepless adjustment |

Max. infeed speed (m/min) |

40 |

40 |

Drilling diameter (mm) |

Ф17.5~Ф40 |

Ф17.5~Ф40 |

Stroke of spindle (mm) |

180 |

180 |

Processing precision |

Accordance with GB2694-81 |

|

Programming mode |

Lofting software or manual program |

|

Overall dimensions (m) |

About 32×8.9×3.2 |

About 32×8.9×3.2 |

Weight of machine (kg) |

About 17000 |

About 18800 |

1. Spindle anti-lock brakes device have obtained national patent.

2. Adopt CNC technology, servo motor infeeding, with high efficiency, stable workpiece precision.

3. Key hydraulic, pneumatic and electric parts all imported.

4. Easy programming and can directly use the program data made by lofting software.

5. Computer with Chinese/English interface, easy operation, and can display the drawing of workpiece.

6. All marking and drilling in automatic completeness, all finished angles can be unloaded by pneumatic turnover device so as to lighten the working strength.

7. Only need to input size of workpiece, diameter of holes, stadia and quantity of workpiece when edit program.

8. With self-diagnosis failures function.

9. Can be installed shearing unit (Max. Thickness to 20mm) or sawing unit (Max. Thickness to 35mm) according to requirements. This function is optional.