Professional Manufacturer of CNC Angle line, angle punching machine, plate processors, plate punching machine, plate drilling machine, beam drill saw line and other machines for Iron tower, steel structure and metal steel sheets.

- APLD1010/APLD1010C CNC Angle Punching Marking&Shearing Line

- APL1412,APLD1412,APLD1412A CNC Angle Punching Marking&Shearing Line

- APL1516,APL1516A (Enhanced)CNC Angle Punching Marking&Shearing Line

- APL2020, APLH2020, APLD2020 CNC Angle Punching Marking&Shearing Line

- APL2532, APL3640 CNC Angle Drilling Marking Line

- APLH2532, APLH3635 CNC High Speed Angle Drilling Marking Line

- CPP103, CPP123 CNC Steel Plate Punching Marking Machine

- CPD103, CPD104 CNC Hydraulic Plate Punching Marking Drilling Machine

- CPP067 CNC Hydraulic Plate Punching Machine

- PL065A CNC Flat Bar Channel Steel Punching Marking&Shearing Line

- AHM100 Hydraulic Marking Machine

- MFP140 Hydraulic Notching Machine

- DPD1610, DPD2016, DPD3016 CNC Plate Drilling Machine

- PLD2012, PLD2016, PLD3016 CNC Steel Plate Drilling Machine

- PHD2012/PHD2016/PHD3016 High Speed CNC Drilling Machine

- PHD2020/PHD3030/PHD4040 High Speed CNC Drilling Machine

- TDD400 TDD700 Beam Drilling Machine

- TDD1000 TDD1250 CNC Beam Drilling Machine

- THD1000 THD1250 CNC High Speed Beam Drilling Machine

- VBS1000 VBS1250 Band Saw

- NBS1000 NBS1250 CNC High Speed Band Saw Machine

- LBM38 LBM55 CNC Beam Beveling Machine

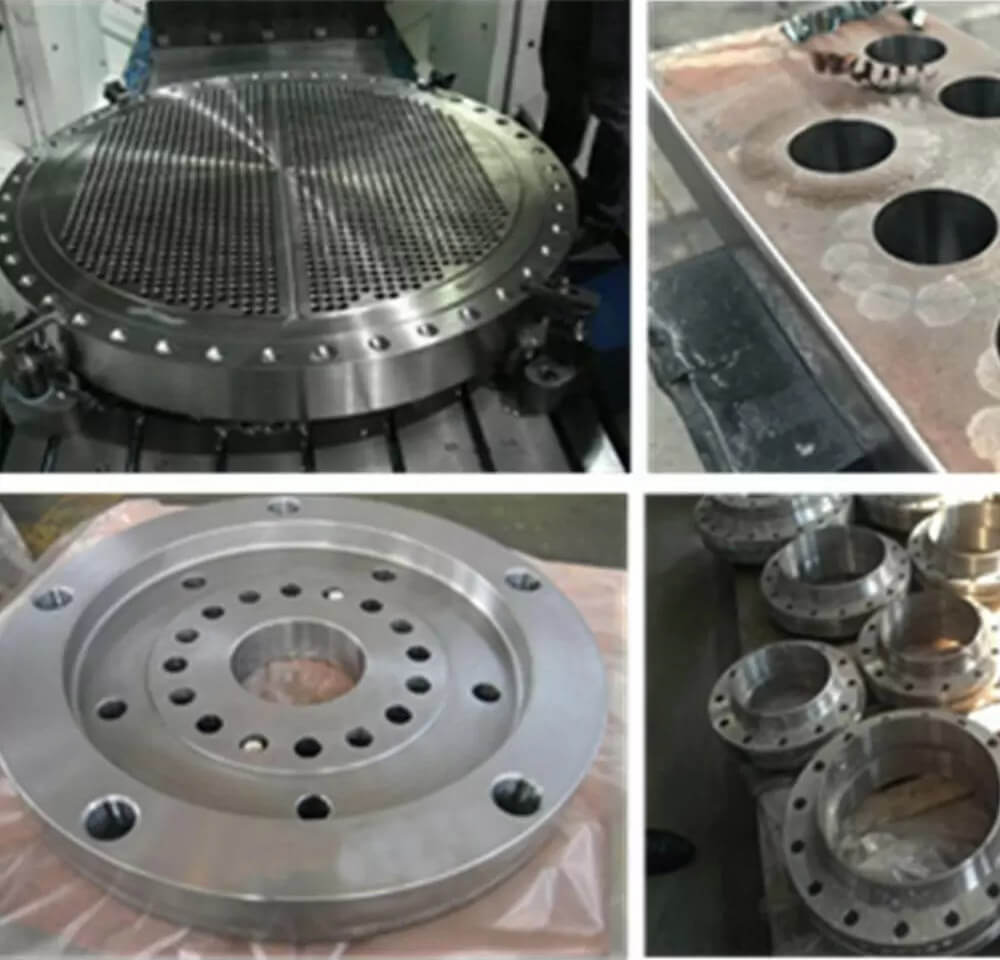

This series metal plate drilling machine is the automatic special equipment used for drilling, tapping, milling steel plate, flanges, tube sheets, mainly in the field of steel structure, boiler, heat-exchanger and so on. This machine also can drill through hole, blind hole, ladder hole.

1. CNC slide way drilling spindle (Z axis) with work piece of stroke is pre-set, realized auto switch. It can drill not only through-hole, but also blind-hole with characteristics of high efficiency, simple structure, low-cost maintenance, easy operation etc.

2. There are 12 hydraulic clamps & T slots for fixing workpieces, easy to operate, save time, and improve production efficiency.

3. This machine has three CNC axis: gantry moving direction (x-axis); drilling head moving direction (y-axis); Spindle feeding direction (z axis). Machine equip each axis with linear guide and ball screw which drived by high precision servo motor.

4. Machine have scrap cleaner which collects iron scraps and cutting liquid.

5. The machine is equipped with an automatic lubrication system for linear guides and ball screws.

6. Machine adopts SIEMENS 808D system, also equipped with computer for drawing and workpiece program processing, easy to operate.

7. The configuration of the machine, like ball screws, linear guides, main electrical parts, servo motors, inverter, etc., all famous brands.

| Model | PHD2012 | PHD2016 | PHD3016 | |

| Max. size of workpiece (mm) | Max. hole distance L×W (mm) | 2000x1200 | 2000x1600 | 3000x1600 |

| Max. thickness (mm) | 200 | 200 | 200 | |

| Drilling spindle | Quantity | 1 | 1 | 1 |

| Spindle taper | BT50 | BT50 | BT50 | |

| Max. diameter of drilling (mm) | Φ40 (carbide drill) Φ50 (high speed twist drill) | |||

| Rotation speed (conver, stepless) (r/min) | 30~3000 | 30~3000 | 30~3000 | |

| Motor power of spindles (kW) | 18.5 | 18.5 | 18.5 | |

| Spindle nether surface to work table (mm) | 200~700 | 200~700 | 200~700 | |

| Longitudinal movement of gantry (X axis) | Max. stroke (mm) | 2000 | 2000 | 3000 |

| X axis feeding speed (m/min) | 0~7 | 0~7 | 0~7 | |

| X axis servo motor power (kW) | 2 | 2 | 2 | |

| Positioning precision | ≤0.08/ (Full length) | ≤0.08/ (Full length) | ≤0.08/ (Full length) | |

| Horizontal move (Y axis) | Max. Stroke (mm) | 1200 | 1600 | 1600 |

| Y axis feeding speed (m/min) | 0~7 | 0~7 | 0~7 | |

| Y axis servo motor power (kW) | 2 | 2 | 2 | |

| Positioning precision | ≤0.08/ (Full length) | ≤0.08/ (Full length) | ≤0.08/ (Full length) | |

| Vertical move (Z axis) | Z axis Max. stroke (mm) | 500 | 500 | 500 |

| Z axis feeding speed (m/min) | 0-5 | 0-5 | 0-5 | |

| Z axis servo motor power (kW) | 3 | 3 | 3 | |

| Positioning precision | X,Y axis (mm) | ≤0.1/ (Full length) | ≤0.1/ (Full length) | ≤0.1/ (Full length) |

| Re- positioning precision | X,Y axis (mm) | ≤0.05 | ≤0.05 | ≤0.05 |

| Chip removal and cooling | Type of chip-conveyor | Chain-plate type | Chain-plate type | Chain-plate type |

| Quantity of chip-conveyor | 1 | 1 | 1 | |

| Chip-removal speed (m/min) | 1 | 1 | 1 | |

| Motor for swarf conveyor (kW) | 0.75 | 0.75 | 0.75 | |

| Motor for cooling pump (kW) | 3+0.75 | 3+0.75 | 3+0.75 | |