Professional Manufacturer of CNC Angle line, angle punching machine, plate processors, plate punching machine, plate drilling machine, beam drill saw line and other machines for Iron tower, steel structure and metal steel sheets.

- APLD1010/APLD1010C CNC Angle Punching Marking&Shearing Line

- APL1412,APLD1412,APLD1412A CNC Angle Punching Marking&Shearing Line

- APL1516,APL1516A (Enhanced)CNC Angle Punching Marking&Shearing Line

- APL2020, APLH2020, APLD2020 CNC Angle Punching Marking&Shearing Line

- APL2532, APL3640 CNC Angle Drilling Marking Line

- APLH2532, APLH3635 CNC High Speed Angle Drilling Marking Line

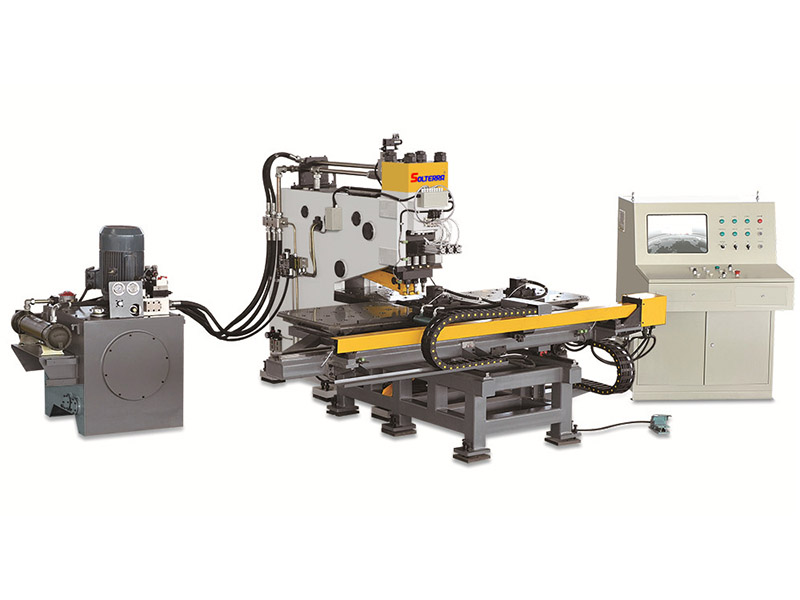

- CPP103, CPP123 CNC Steel Plate Punching Marking Machine

- CPD103, CPD104 CNC Hydraulic Plate Punching Marking Drilling Machine

- CPP067 CNC Hydraulic Plate Punching Machine

- PL065A CNC Flat Bar Channel Steel Punching Marking&Shearing Line

- AHM100 Hydraulic Marking Machine

- MFP140 Hydraulic Notching Machine

- DPD1610, DPD2016, DPD3016 CNC Plate Drilling Machine

- PLD2012, PLD2016, PLD3016 CNC Steel Plate Drilling Machine

- PHD2012/PHD2016/PHD3016 High Speed CNC Drilling Machine

- PHD2020/PHD3030/PHD4040 High Speed CNC Drilling Machine

- TDD400 TDD700 Beam Drilling Machine

- TDD1000 TDD1250 CNC Beam Drilling Machine

- THD1000 THD1250 CNC High Speed Beam Drilling Machine

- VBS1000 VBS1250 Band Saw

- NBS1000 NBS1250 CNC High Speed Band Saw Machine

- LBM38 LBM55 CNC Beam Beveling Machine

Special CNC machine for punching and marking of steel plates in the field of steel tower industry. It is also used to punch and mark of steel plates of other industries.

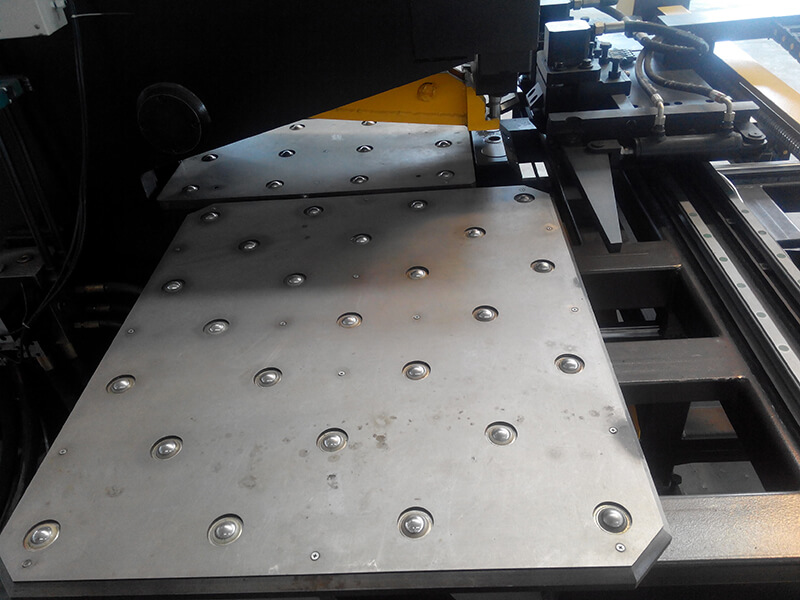

1. The machine-frame is made by C-type plate welding, with good rigidity and big handling space. The machine sets three die-stations (among them, one is the marking die-station), automatic switching die-stations. Clamping system can adapt to different workpiece.

2. Adopt CNC technology, servo motor infeeding, with high efficiency, stable workpiece precision.

3. Important functional components adopt modular assembly, easy to repair it.

4. Carry out punching and marking on the one plate.

5. Easy programming, may input the diameter of holes, position and the quantity of workpiece to computer, and also may use the program generated by lofting software. It can ready TEKLA lofting software files, such as NC1 format.

6. With self-diagnosis failures function.

7. X, Y axis are driven by servo motor + ball screw + linear guide, the precision is better.

| Model | CPP103 | CPP123 |

| Punching force (kN) | 1000 | 1200 |

| Marking force (kN) | 800 | 1000 |

| Thickness of punching (mm) | 6~20/25 (Q345/Q235) | 6~25 (Q420) |

| Max dimension of workpiece (mm) | 1500×775 | 1500×775 |

| Max diameter of punching hole (mm) | Ф25.5 (Q235) | Ф25.5 (Q420) |

| Min margin of punching hole (mm) | 25 | 25 |

| Number of die-stations (piece) | 3 | 3 |

| Dimension of character (mm) | 14×10×19 | 14×10×19 |

| Character number piece | 10 | 10 |

| Speed of X.Y axes (m/min) | 12 | 18 |

| Overall dimension (mm) | 3020×2522×1880 | 3000×2700×1900 |