Professional Manufacturer of CNC Angle line, angle punching machine, plate processors, plate punching machine, plate drilling machine, beam drill saw line and other machines for Iron tower, steel structure and metal steel sheets.

- APLD1010/APLD1010C CNC Angle Punching Marking&Shearing Line

- APL1412,APLD1412,APLD1412A CNC Angle Punching Marking&Shearing Line

- APL1516,APL1516A (Enhanced)CNC Angle Punching Marking&Shearing Line

- APL2020, APLH2020, APLD2020 CNC Angle Punching Marking&Shearing Line

- APL2532, APL3640 CNC Angle Drilling Marking Line

- APLH2532, APLH3635 CNC High Speed Angle Drilling Marking Line

- CPP103, CPP123 CNC Steel Plate Punching Marking Machine

- CPD103, CPD104 CNC Hydraulic Plate Punching Marking Drilling Machine

- CPP067 CNC Hydraulic Plate Punching Machine

- PL065A CNC Flat Bar Channel Steel Punching Marking&Shearing Line

- AHM100 Hydraulic Marking Machine

- MFP140 Hydraulic Notching Machine

- DPD1610, DPD2016, DPD3016 CNC Plate Drilling Machine

- PLD2012, PLD2016, PLD3016 CNC Steel Plate Drilling Machine

- PHD2012/PHD2016/PHD3016 High Speed CNC Drilling Machine

- PHD2020/PHD3030/PHD4040 High Speed CNC Drilling Machine

- TDD400 TDD700 Beam Drilling Machine

- TDD1000 TDD1250 CNC Beam Drilling Machine

- THD1000 THD1250 CNC High Speed Beam Drilling Machine

- VBS1000 VBS1250 Band Saw

- NBS1000 NBS1250 CNC High Speed Band Saw Machine

- LBM38 LBM55 CNC Beam Beveling Machine

This CNC beam beveling machine is used for the milling of gloves of H-shape steel and box beams in the field of steel structure, 3-dimensional garage and petrol platform.

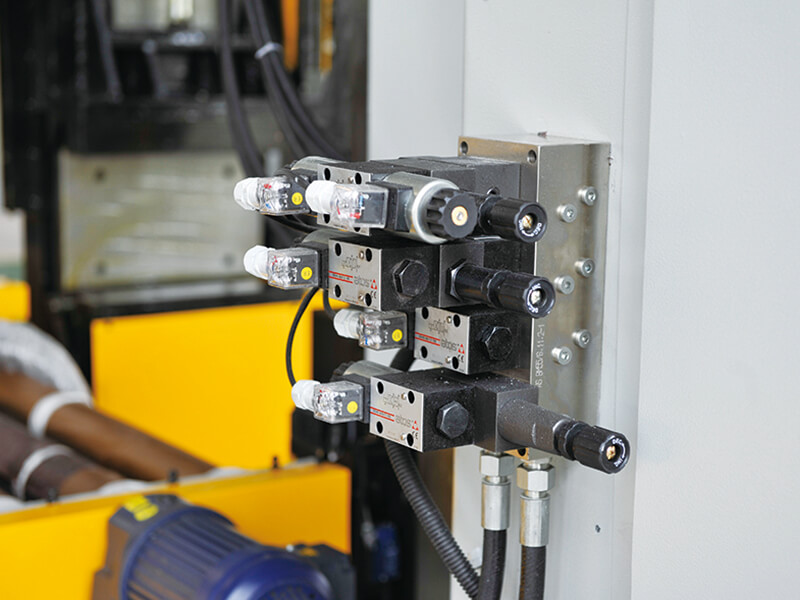

1. The CNC beam beveling machine is mainly composed of longitudinal and transverse slipway, milling head, milling columns, stopper-mechanism, rollerway, hydraulic system, electrical system.etc.

2. The machine body is welded between square steel tube and steel plate with a framework structure. The cnc cutting machine possesses strong rigidity and strong processing power. High precision and high stability be realized.

3. Every spindle box includes three mills, bevel the arcnotch, end-surface and web of H-beam in once feeding to finish all processing. Adopted indexable carbide, milling head, high grade milling head ensured the efficiency of the machine; every milling head can be use many times through adjusting the position of the edge, the customer can save the cost.

4. Adopted touching screen input as human-computer interface, English or Chinese operation, simple processing data, the operator can operate easily.

5. Six CNC milling spindles.

6. Bevel the arcnotch, end-surface and web of H-beam in once processing course.

7. The sloping port milling head spindle can be adjusted by axis direction, to process different size of sloping ports. In the milling processing, the milling feeding speed can be adjusted automatically according to different processing position, increase the efficiency and protect the milling head.

8. The machine is belonged to the type of automatic product line, composed of infeed conveyor, main machine, outfeed conveyor etc., can automatically milling the same type H-beams continuously.

| Model | LBM 38/6 | LBM55/6 | |

| Workpiece | Web height (mm) | 220-1000 | 220-1250 |

| Flange edge width (mm) | 100-600 | 100-600 | |

| Flange thickness (mm) | 10-38 | 10-55 | |

| Workpiece length (mm) | ≥400 | ≥400 | |

| Milling unit with three spindles | Quantity | 2 | 2 |

| (Unit)Head quantiy | 6 | 6 | |

| Motor power of spindles (kW) | 2x15 | 2x15 | |

| Up/down speed (frequency conversion, CNC)(mm/min) | 100-600 | 100-600 | |

| Motor power for up and down (kW) | 2x1.5 | 2x2.2 | |

| Control mode | PLC | PLC | |

| Overall dimensions (L×W×H)(mm) | 7300×2900×2000 | 7300×3100×2000 | |

| Machine weight (kg) | (Appr.)5000 | (Appr.)5500 | |