Professional Manufacturer of CNC Angle line, angle punching machine, plate processors, plate punching machine, plate drilling machine, beam drill saw line and other machines for Iron tower, steel structure and metal steel sheets.

- APLD1010/APLD1010C CNC Angle Punching Marking&Shearing Line

- APL1412,APLD1412,APLD1412A CNC Angle Punching Marking&Shearing Line

- APL1516,APL1516A (Enhanced)CNC Angle Punching Marking&Shearing Line

- APL2020, APLH2020, APLD2020 CNC Angle Punching Marking&Shearing Line

- APL2532, APL3640 CNC Angle Drilling Marking Line

- APLH2532, APLH3635 CNC High Speed Angle Drilling Marking Line

- CPP103, CPP123 CNC Steel Plate Punching Marking Machine

- CPD103, CPD104 CNC Hydraulic Plate Punching Marking Drilling Machine

- CPP067 CNC Hydraulic Plate Punching Machine

- PL065A CNC Flat Bar Channel Steel Punching Marking&Shearing Line

- AHM100 Hydraulic Marking Machine

- MFP140 Hydraulic Notching Machine

- DPD1610, DPD2016, DPD3016 CNC Plate Drilling Machine

- PLD2012, PLD2016, PLD3016 CNC Steel Plate Drilling Machine

- PHD2012/PHD2016/PHD3016 High Speed CNC Drilling Machine

- PHD2020/PHD3030/PHD4040 High Speed CNC Drilling Machine

- TDD400 TDD700 Beam Drilling Machine

- TDD1000 TDD1250 CNC Beam Drilling Machine

- THD1000 THD1250 CNC High Speed Beam Drilling Machine

- VBS1000 VBS1250 Band Saw

- NBS1000 NBS1250 CNC High Speed Band Saw Machine

- LBM38 LBM55 CNC Beam Beveling Machine

This machine combines three functions is one device, used for punching, marking and shearing angles. So it's called CNC angle production line.

The machine is the automatic special production line used for angle steel marking, punching, and shearing mainly in the field of angle steel tower industry, electric power fittings, structure storage facilities, bridge and steel structure construction industries etc.

1. Transverse Conveyor |

2. Rotating Loading System with Rotating Motor |

3. Infeed Conveyor and CNC Controlled Carriage |

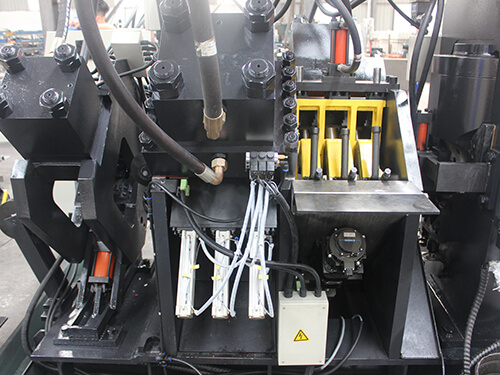

4. Machine Host Including Punching, Marking & Shearing Unit |

5. Unloading Conveyor |

6. Hydraulic Unit |

7. Electrical Cabinet |

1. Angle processing size: 40×40×3-150×150×16mm.

2. Functions: Punching, Marking, Shearing.

3. Quantity punches on each side: 3 punches (Customer can set three different diameter of punches at the same time.)

4. NC carriage feeding, more faster and precision more higher.

5. Double accumulators(Which are located above the host and the hydraulic station), improve the speed of punching and production efficiency.

6. Single blade cutting, no scraps.

Model |

TAPM1516 |

TAPM1516S |

Functions |

Punching, marking, shearing |

Punching, marking, shearing |

Angle size (mm) |

40×40×3~150×150×16 |

40×40×3~150×150×16 |

Max. punching (dia. × thi.) (mm) |

Ф26×16(Q345) |

Ф26×16(Q420) |

Punching force (kN) |

1000 |

1200 |

Marking force (kN) |

800 |

1030 |

Shearing force (kN) |

1800 |

2400 |

Max. length of blank (m) |

12 or 14 |

12 or 14 |

Max. length of finished (m) |

10 |

10 |

Qty. of punch on each side (piece) |

3 |

3 |

Qty. of marking group |

4 |

4 |

Character size (mm) |

14×10×19 |

14×10×19 |

CNC axis |

3 |

3 |

Shearing mode |

Single blade shearing |

Single blade shearing |

Angle feeding speed (m/min) |

80 |

80 |

Processing precision |

Accordance with GB2694 |

Accordance with GB2694 |

Working environment |

Temperature: -10°~40°; Voltage: 380V.50HZ, 3 phase; Voltage range: ±10% |

Temperature: -10°~40; Voltage:380V.50HZ, 3 phase; Voltage range: ±10% |

Overall dimensions (m) |

About 25×7.5×3 |

About 25×7.5×3 |

Net weight of machine (kg) |

About 16500 |

About 17300 |

1. Adopt CNC technology, servo motor infeeding, with high efficiency, stable workpiece precision. Key hydraulic, pneumatic and electric parts all imported.

2. There are three sets of punch and die on each side which can install three kinds of punches with different diameters. Three sets of moulds can move altogether controlled by PLC to change the punching back mark.

3. Computer with Chinese/English interface, easy operation, and can display the drawing of workpiece. Easy programming and can directly use the program data made by lofting software. Only need to input size of workpiece, diameter of holes, back mark and quantity of workpiece when edit program.

4. CNC infeed carriage is driven by servo motor. The photoelectric encoder feeds back the information. Closed loop control to ensure high positioning precision.

5. All marking, punching and shearing in automatic completeness, all finished angles can be unloaded by pneumatic turnover device so as to lighten the working strength.

6. The control system consists of the host computer, CNC system, servo motor, PLC, external examination sensors, etc. Just input the dimension of workpiece, the processing will be created. Furthermore, the program can be stored, selected, displayed and communicated as per the workpiece No..

7. Marking unit adopts closed frame with good rigidity. Four groups of character boxes are fixed on the marking unit which can be selected by program. Marking stadia can be set at will.

8. Single blade shearing, shearing section is smooth and save raw material.