Professional Manufacturer of CNC Angle line, angle punching machine, plate processors, plate punching machine, plate drilling machine, beam drill saw line and other machines for Iron tower, steel structure and metal steel sheets.

- APLD1010/APLD1010C CNC Angle Punching Marking&Shearing Line

- APL1412,APLD1412,APLD1412A CNC Angle Punching Marking&Shearing Line

- APL1516,APL1516A (Enhanced)CNC Angle Punching Marking&Shearing Line

- APL2020, APLH2020, APLD2020 CNC Angle Punching Marking&Shearing Line

- APL2532, APL3640 CNC Angle Drilling Marking Line

- APLH2532, APLH3635 CNC High Speed Angle Drilling Marking Line

- CPP103, CPP123 CNC Steel Plate Punching Marking Machine

- CPD103, CPD104 CNC Hydraulic Plate Punching Marking Drilling Machine

- CPP067 CNC Hydraulic Plate Punching Machine

- PL065A CNC Flat Bar Channel Steel Punching Marking&Shearing Line

- AHM100 Hydraulic Marking Machine

- MFP140 Hydraulic Notching Machine

- DPD1610, DPD2016, DPD3016 CNC Plate Drilling Machine

- PLD2012, PLD2016, PLD3016 CNC Steel Plate Drilling Machine

- PHD2012/PHD2016/PHD3016 High Speed CNC Drilling Machine

- PHD2020/PHD3030/PHD4040 High Speed CNC Drilling Machine

- TDD400 TDD700 Beam Drilling Machine

- TDD1000 TDD1250 CNC Beam Drilling Machine

- THD1000 THD1250 CNC High Speed Beam Drilling Machine

- VBS1000 VBS1250 Band Saw

- NBS1000 NBS1250 CNC High Speed Band Saw Machine

- LBM38 LBM55 CNC Beam Beveling Machine

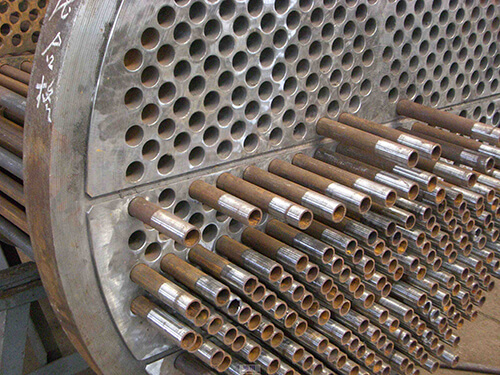

Used for the drilling processing for tube plate, clapboard and flange, in petrochemical, boiler, and wind power flange industries, also for joint plates in building, bridge, iron tower, etc.

1. Worktable For Square and Round Work-piece |

2. Thickened and Enhanced Movable Gantry |

3. Drill Head |

4. Electric Cabinet with CNC System |

5. Hydraulic Station |

6. Automatic Chip Conveyor with Chip Carriage |

7. Automatic Recycling Cooling Water System |

1. Function: Drilling, Tapping, Milling, Chamfering and so so.

2. Work-piece: Steel Plates, Flanges, Tube Sheets, Pressure Vessels and so on.

3. High precision: ±0.1mm.

Model |

TPHD2020 |

TPHD2525 |

TPHD3030 |

|

Max. size of workpiece (mm) |

Max. hole distance L×W (mm) |

2000×2000 |

2500×2500 |

3000×3000 |

Max. thickness (mm) |

300 |

|||

Worktable |

Width/distance of T groove (mm) |

28/500 |

||

Drilling spindle |

Quantity |

2 |

||

Spindle taper |

BT50 |

|||

Max. diameter of drilling (mm) |

Φ40Φ50 |

|||

Rotation speed(stepless) (r/min) |

30~2000 |

|||

Motor power of spindles (kW) |

2×22 |

|||

Spindle nether surface to work table (mm) |

280~780 |

|||

(X axis) Longitudinal movement of gantry |

Max. stroke (mm) |

2000 |

2500 |

3000 |

X axis feeding speed (m/min) |

0~8 |

|||

X axis servo motor power (kW) |

2×3 |

|||

(Y axis) Horizontal move |

Max. distance of spindles (mm) |

2000 |

2500 |

300 |

Y axis feeding speed (m/min) |

0~8 |

|||

Y axis servo motor power (kW) |

2×3 |

|||

(Z axis) Vertical move |

Z axis Max. stroke (mm) |

500 |

||

Z axis feeding speed (m/min) |

0-4 |

|||

Z axis servo motor power (kW) |

2×3 |

|||

Positioning precision |

X,Yaxis |

≤0.1/ (full length) |

||

Re-positioning precision |

X,Yaxis |

≤0.05 |

||

Hydraulic system |

Hydraulic pump (Mpa)/ (L/min) |

7 /25 |

||

Motor for hydraulic pump (kW) |

3 |

|||

Chip removal and cooling |

Type of chip-conveyor |

Chain-plate type |

||

Quantity of chip-conveyor |

1 |

|||

Chip-removal speed (m/min) |

1 |

|||

Motor for swarf conveyor (kW) |

0.75 |

|||

Motor for cooling pump (kW) |

2×3+0.75 |

|||

Overall dimension |

L×W×H (m) |

Appr. 5.2×5.1×3.6 |

Appr. 5.7×5.6×3.6 |

Appr. 6.2×6.1×3.6 |

Weight of machine (t) |

Appr. 30 |

Appr. 35 |

Appr. 40 |

|

1. Servo slide drilling unit heads, with the function of drilling holes, reaming, chamfering angle, milling of groove, can work together, or work separately.

2. Automatically find pot to dill holes in X,Y axis. Spindle rotation speed and feed velocity are stepless adjustment.

3. T-groove is set on lathe bed, using pressure plate to clamp workpiece.

4. To seek workpiece center in hand-operated wheel, thimble.

5. Programming software based on WINDOWS platform with CAD connection, fast and convenient programming, and visual previewing.

6. Automatic chip removal, coolant circulation cooling.

7. Key machinery, hydraulic pressure, electric components are chose from famous cooperation domestic and abroad.

8. First choice equipment of tube plate drilling in heat exchange, chemical & mechanical industry.

9. Controlled by CNC, PLC system; Shown by CRT.