Professional Manufacturer of CNC Angle line, angle punching machine, plate processors, plate punching machine, plate drilling machine, beam drill saw line and other machines for Iron tower, steel structure and metal steel sheets.

- APLD1010/APLD1010C CNC Angle Punching Marking&Shearing Line

- APL1412,APLD1412,APLD1412A CNC Angle Punching Marking&Shearing Line

- APL1516,APL1516A (Enhanced)CNC Angle Punching Marking&Shearing Line

- APL2020, APLH2020, APLD2020 CNC Angle Punching Marking&Shearing Line

- APL2532, APL3640 CNC Angle Drilling Marking Line

- APLH2532, APLH3635 CNC High Speed Angle Drilling Marking Line

- CPP103, CPP123 CNC Steel Plate Punching Marking Machine

- CPD103, CPD104 CNC Hydraulic Plate Punching Marking Drilling Machine

- CPP067 CNC Hydraulic Plate Punching Machine

- PL065A CNC Flat Bar Channel Steel Punching Marking&Shearing Line

- AHM100 Hydraulic Marking Machine

- MFP140 Hydraulic Notching Machine

- DPD1610, DPD2016, DPD3016 CNC Plate Drilling Machine

- PLD2012, PLD2016, PLD3016 CNC Steel Plate Drilling Machine

- PHD2012/PHD2016/PHD3016 High Speed CNC Drilling Machine

- PHD2020/PHD3030/PHD4040 High Speed CNC Drilling Machine

- TDD400 TDD700 Beam Drilling Machine

- TDD1000 TDD1250 CNC Beam Drilling Machine

- THD1000 THD1250 CNC High Speed Beam Drilling Machine

- VBS1000 VBS1250 Band Saw

- NBS1000 NBS1250 CNC High Speed Band Saw Machine

- LBM38 LBM55 CNC Beam Beveling Machine

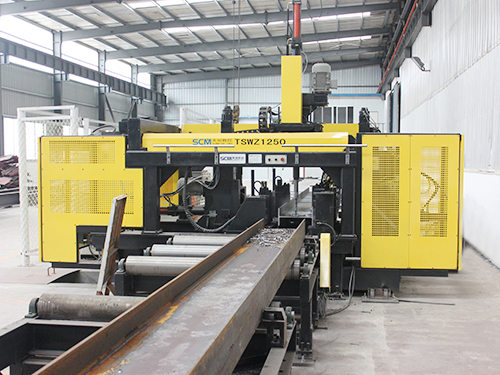

Used for the drilling processing of H-shape steel, box beam and channel steel of steel structure, bridge, three dimensional garage and petrol platform industries.

1. Work-piece: H U Beams.

2. Functions: Drilling, Marking (Optional Unit).

3. Quantity of drilling head: Three(Top, Left and Right).

4. Feeding mode: Automatic NC Feeding carriage --- High feeding speed, High precision.

Model |

TSWZ1000 |

TSWZ1250 |

||||

Workpiece size |

H-beams Max. (web height×flange width) (mm) |

Max. |

1000x500 |

1250x600 |

||

Min. |

150x75 |

|||||

Length (mm) |

Auto feeding |

≥3000 |

||||

Manual feeding |

≥690 |

|||||

Thickness of web & flange (mm) |

80 |

|||||

Drill dia. (mm) |

Vertical drilling |

Φ12~Φ33.5 |

||||

Horizontal drilling |

Φ12~Φ26.5 |

|||||

Spindles |

No. of spindle |

One spindle on each of three sides (top, left, right) Total: 3 spindles |

||||

Rotation speed (stepless speed adjustment) (rpm) |

180~650 |

|||||

Spindle motor power(KW) |

3x4 kW |

|||||

Max. feeding stroke (mm) |

Left, Right: 140 Vertical: 325 |

|||||

Feeding speed (mm/min) |

20~300 |

|||||

Movement of left/right spindle (mm) |

In the direction of workpiece length: 520 |

|||||

Above vertical base-level: 30~470 |

Above vertical base-level: 30~570 |

|||||

Movement of top spindle (mm) |

In the direction of workpiece length: 520 |

|||||

Beyond horiizontal base-level: 45~910 |

Beyond horiizontal base-level: 45~1160 |

|||||

Marking |

No. of characters |

36 characters |

||||

Character size (mm) |

Φ10 |

|||||

Overall dimensions (L*W*H)(mm) |

4550x3050x3520 |

4800x3050x3520 |

||||

Total power (kW) |

34 |

|||||

Machine weight (kg) |

Appr.7000 |

Appr.8000 |

||||

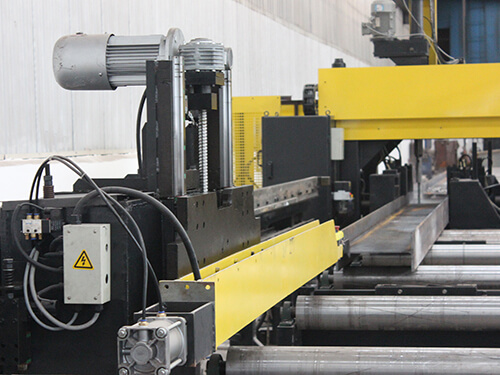

1. Frame made of sturdy electro-welded and normalized Plates and Square Beams. The structure with roller guides on which the sliders supporting the three spindles guarantees the total moving stability, and ensures the working precision;

2. Three drilling spindles mounted on individual moving platform can equip with carbide drills. The spindles' feeding and feedback (for exact spindle positioning) is done through 3 sets of powerful hydraulic cylinders or servo motors.

3. The sensor system automatically calculates the centerline of the beam. This permits flanges holes to be accurately positioned at given dimensions above or below the web centerline, or web holes to be located from a centerline reference.

4. The control system is a Computer based with PLC and modules controlled system. The computer facilitates the operator to design, revise, and transmitting program, or manually makes up the program. The numerical control like, PLC, modules, servos, etc. are all developed by MITSUBISHI to facilitate program creation and provide appreciable operational savings.

5. This machine can read AUTOCAD drawings and lofting software files automatically, such as DXF, NC1.

6. Equipped with automatic lubrication system and air conditioner for electric cabinet.

7. Equipped with automatic feeding systems, which will clamp and feed material into machine automatically.