Professional Manufacturer of CNC Angle line, angle punching machine, plate processors, plate punching machine, plate drilling machine, beam drill saw line and other machines for Iron tower, steel structure and metal steel sheets.

- APLD1010/APLD1010C CNC Angle Punching Marking&Shearing Line

- APL1412,APLD1412,APLD1412A CNC Angle Punching Marking&Shearing Line

- APL1516,APL1516A (Enhanced)CNC Angle Punching Marking&Shearing Line

- APL2020, APLH2020, APLD2020 CNC Angle Punching Marking&Shearing Line

- APL2532, APL3640 CNC Angle Drilling Marking Line

- APLH2532, APLH3635 CNC High Speed Angle Drilling Marking Line

- CPP103, CPP123 CNC Steel Plate Punching Marking Machine

- CPD103, CPD104 CNC Hydraulic Plate Punching Marking Drilling Machine

- CPP067 CNC Hydraulic Plate Punching Machine

- PL065A CNC Flat Bar Channel Steel Punching Marking&Shearing Line

- AHM100 Hydraulic Marking Machine

- MFP140 Hydraulic Notching Machine

- DPD1610, DPD2016, DPD3016 CNC Plate Drilling Machine

- PLD2012, PLD2016, PLD3016 CNC Steel Plate Drilling Machine

- PHD2012/PHD2016/PHD3016 High Speed CNC Drilling Machine

- PHD2020/PHD3030/PHD4040 High Speed CNC Drilling Machine

- TDD400 TDD700 Beam Drilling Machine

- TDD1000 TDD1250 CNC Beam Drilling Machine

- THD1000 THD1250 CNC High Speed Beam Drilling Machine

- VBS1000 VBS1250 Band Saw

- NBS1000 NBS1250 CNC High Speed Band Saw Machine

- LBM38 LBM55 CNC Beam Beveling Machine

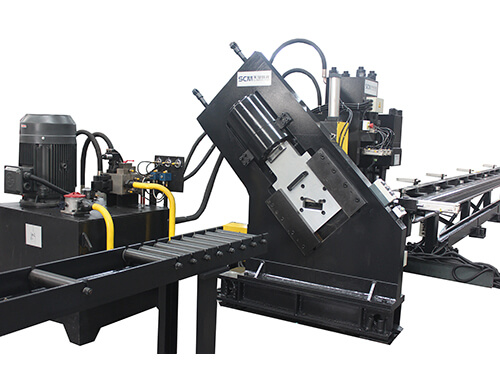

TPL9004 CNC Hydraulic Punching,Marking & Shearing Line For Flat Bar And Channel

This machine is the automatic special equipment used for flat bar and channel steel marking, punching, and shearing mainly in the field of angle steel tower industry.

Product Feature of TPL9004 CNC Hydraulic Punching Machine

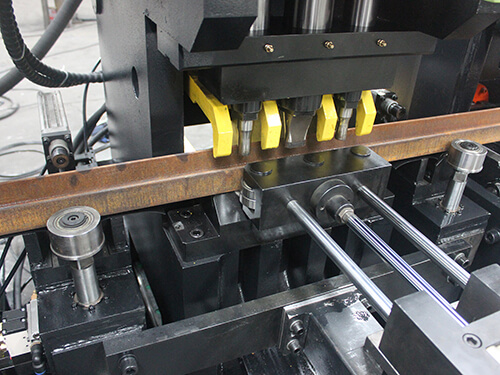

1. Adopt CNC technology,servo motor infeeding,with high efficiency, stable workpiece precision.

2. Key hydraulic,pneumatic and electric parts all famous brands.

3. Computer with Chinese/English interface,easy operation, and can display the drawing of workpiece.

4. All marking,punching and shearing in automatic completeness.

5. Automatic chip removal, circular coolant.

6. Only need to input size of workpiece,diameter of holes and quantity of workpiece when edit program.

7.Fast marking speed.

8.Flat end with single-blade cutting; Circular arc end with double-blade cutting;

9.With self-diagnosis failures function.

Model |

TPL9004-12 |

TPL9004-16 |

Max.Workpiece Length(mm) |

9000 |

|

Workpiece Width(mm) |

40~120 |

40~160 |

Channel Size(mm) |

#6.3~#12 |

#6.3~#16 |

Max.punching Diameter(mm) |

Φ26 |

|

Slot Hole(mm) |

22X50 |

|

Max.thickNess(mm) |

12 |

|

Punching Force(kN) |

1000 |

|

Qty. of Punching Die-station |

3 |

|

Marking Force(kN) |

800 |

|

Qty. of Marking Die-station |

1 |

|

Character Size(mm) |

14×10×19 |

|

Qty. of Character Box |

4 |

|

Qty. of Characters |

12 |

|

Cutting Force(kN) |

1200 |

|

Cutting Mode |

Single Blade |

|

Feeding Mode |

NC Carriage |

|

Feeding Speed (m/min) |

60 |

|

Program Function |

Error Display |

|

1.PLC systems, LCD screen display, programming Microsoft based on WINDOWS platform, fast and convenient programming, and visual previewing.

2. Main machine, hydraulic pressure, electric components are famous products domestic and abroad.

3.Equipped with automatic feeding system, which will clamp and feeding material into machine automatically.

4.Double linear guides’ infeeding, precision much higher and more stable.